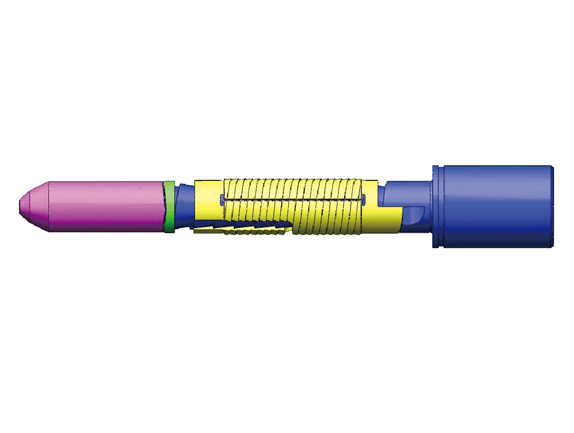

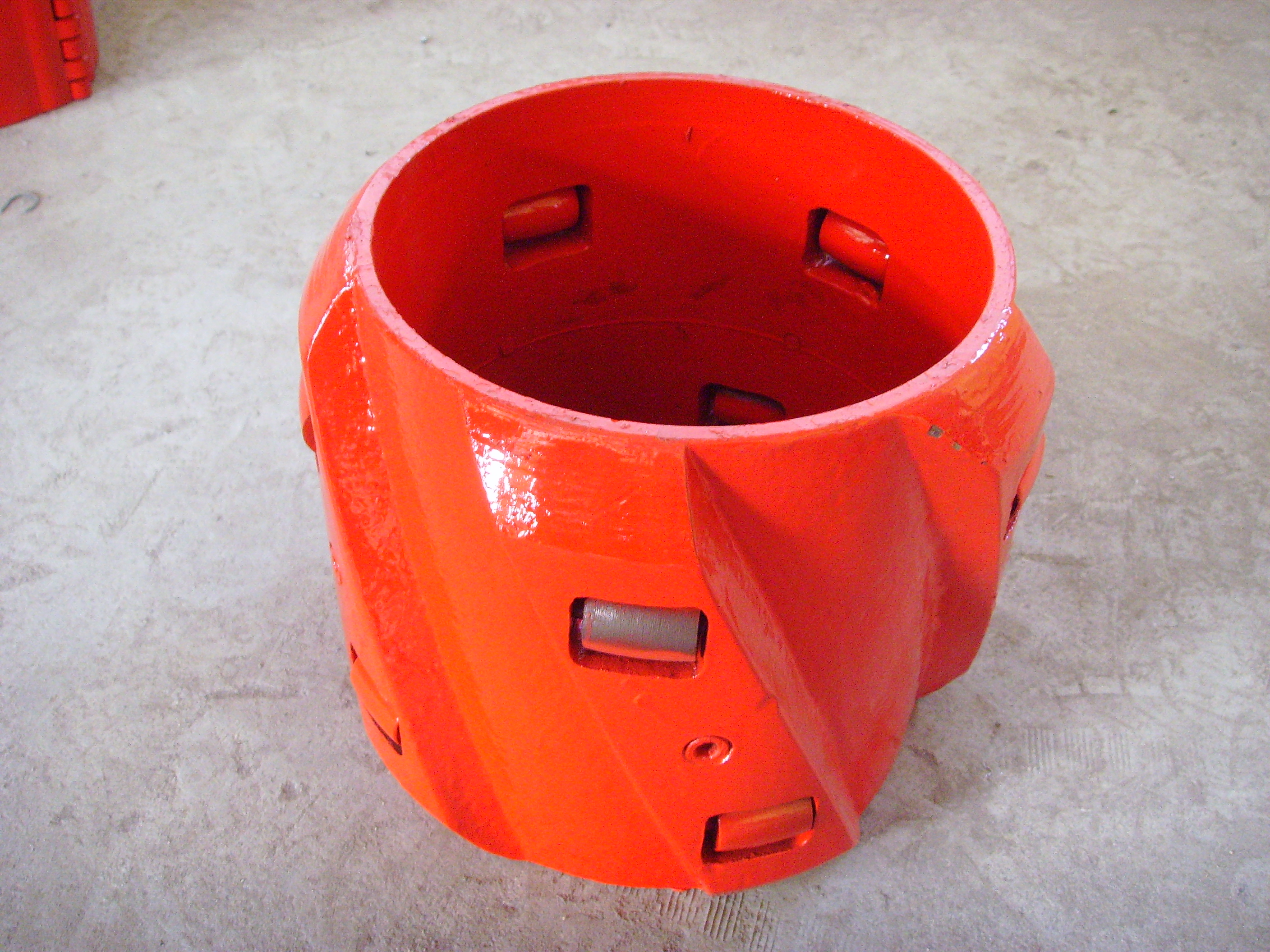

Two rows of rollers are horizontally installed on the centralizing edge of the roller centralizer, and the roller axis of the centralizer is perpendicular to the wellbore axis. When the casing enters the inclined well section, on the one hand, the large section of the casing body is not close to the low side of the wellbore, and the friction area is reduced; on the other hand, due to the rolling of the rollers, the sliding friction during conventional casing running It becomes rolling friction, which greatly reduces the friction coefficient between the casing and the well wall, and makes the casing enter the well smoothly.

en

en

cn

cn  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  pl

pl  vi

vi  hu

hu

Call us on:

Call us on:  Email Us:

Email Us:  No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China

No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China