1. Apply WOB to the drill bit;

2. Ensure the necessary strength under compression conditions;

3. Reduce the vibration, swing, and jump of the drill bit, so that the drill bit works smoothly;

4. Control well deviation

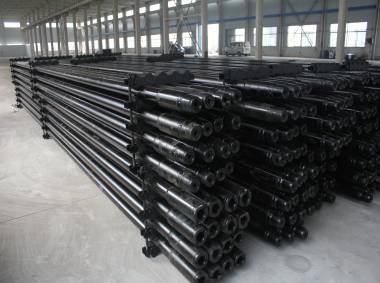

Product specifications

1) Product size 3-1/8" to 14"

2) Bar grade: 4145H; 4145H-MOD; P530; P550

3) Product type: smooth drill pipe, spiral drill collar, non-magnetic drill collar

4) Product length: 30 feet, 31 feet or according to customer special requirements

5) Thread type: from NC23 to 6-5/8REG; 7-5/8REG; 8-5/8REG; 8-5/8H90

6) Drill collar specifications: APISPEC7-1, APISPEC 7-2 and API RP7G

VIDEO

Drill Collar Number

Outside Diameter

Inside Diameter

Length

Bevel dia.

Ref.Bending strength Ratio

Df

mm

in

mm

in

mm

ft

in

NC23-31

79.4

3 1/8

31.8

1 1/4

9150

30

3

2.57:1

NC26-35(2 3/8IF)

88.9

3.5

38.1

1.5

9150

30

3 17/64

2.42 :

1

NC31-41(2 7/8IF)

104.8

4 1/8

50.8

2

9150&9450

30 or 31

3 61/64

2.43 :

1

NC35-47

120.7

4 3/4

50.8

2

9150&9450

30 or 31

4 33/64

2.58 :

1

NC38-50

127

5

57.2

2 1/4

9150&9450

30 or 31

4 49/64

2.38 :

1

NC44-60

152.4

6

57.2

2 1/4

9150&9450

30 or 31

5 11/16

2.49 :

1

NC44-60

152.4

6

71.4

2 13/16

9150&9450

30 or 31

5 11/16

2.84 :

1

NC44-62

158.8

6 1/4

57.2

2 1/4

9150&9450

30 or 31

5 7/8

2.91 :

1

NC46-62

158.8

6 1/4

71.4

2 13/16

9150&9450

30 or 31

5 29/32

3.63 :

1

NC46-65(4IF)

165.1

6.5

57.2

1 1/4

9150&9450

30 or 31

6 3/32

2.76 :

1

NC46-65(4IF)

165.1

6.5

71.4

2 13/16

9150&9450

30 or 31

6 3/32

3.05 :

1

NC-46-67(4IF)

171.4

6.75

57.2

.2 1/4

9150&9450

30 or 31

6 9/32

3.18 :

1

NC50-67

171.4

6.75

71.4

2 13/16

9150&9450

30 or 31

6 9/32

2.37 :

1

NC50-70

177.8

7

57.2

2 1/4

9150&9450

30 or 31

6 31/64

2.54 :

1

NC50-70(4 1/2 IF)

177.8

7

71.4

2 13/16

9150&9450

30 or 31

6 31/64

2.73 :

1

NC50-72

184.2

7 1/4

71.4

2 13/16

9150&9450

30 or 31

6 43/64

3.12 :

1

NC56-77

196.6

7 3/4

71.4

2 13/16

9150&9450

30 or 31

7 19/64

2.70:1

NC56-80

203.2

8

71.4

2 13/16

9150&9450

30 or 31

7 31/64

3.02 :

1

6 5/8 REG

209.6

8 1/4

71.4

2 13/16

9150&9450

30 or 31

7 45/64

2.93 :

1

NC61-90

228.6

9

71.4

2 13/16

9150&9450

30 or 31

8 3/8

3.17 :

1

7 5/8 REG

241.3

9 1/2

76.2

3

9150&9450

30 or 31

8 13/16

2.81 :

1

NC70-97

247.6

9 3/4

76.2

3

9150&9450

30 or 31

9 5/32

2.57 :

1

NC70-100

254

10

76.2

3

9150&9450

30 or 31

9 11/32

2.81 :

1

8 5/8 REG

279.4

11

76.2

3

9150&9450

30 or 31

10 1/2

2.84 :

1

Note:

1. Effective Length range:30ft or 31ft.

2. Joint tool thread cold working(C/W).

3.(SRG)stress relief groove and bore back box. Manufactured according to API 7-1 latest version.

en

en

cn

cn  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  pl

pl  vi

vi  hu

hu

Call us on:

Call us on:  Email Us:

Email Us:  No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China

No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China