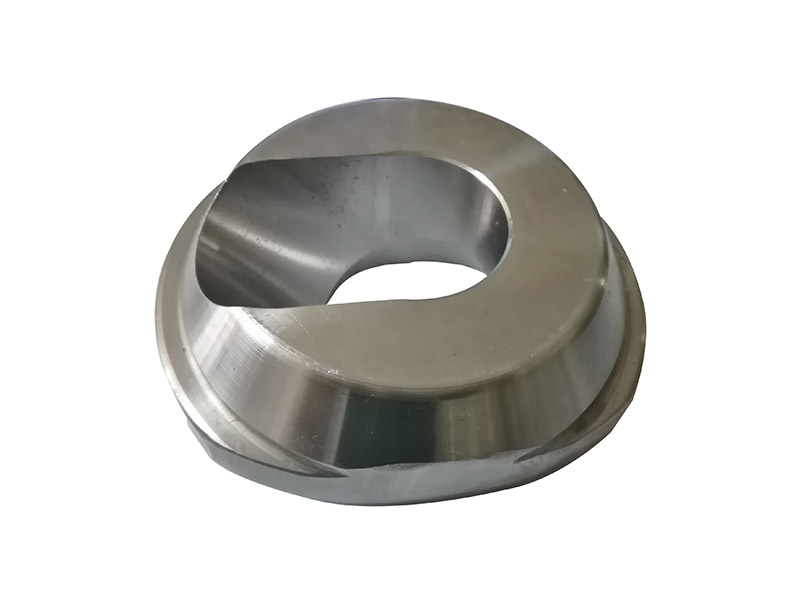

●Standard cement rubber plug is suitable for various floating hoops and floating shoes; anti-rotation cement rubber plug is suitable for anti-transition floating hoops and floating shoes.

●The top plug and bottom plug are designed with two-stage seals and scraping wings.

●Scraping wings made of wear-resistant materials.

●The anti-rotation rubber plug is designed with an anti-rotation mechanism, which can greatly increase the drilling speed.

●PDC bit or cone bit can be drilled.

Instructions

The upper rubber plug and the lower rubber plug are generally used in sets. The upper rubber plug separates the upper cement slurry and mud to prevent the cement slurry from being contaminated and at the same time replace the cement slurry to the annulus.

Put the lower rubber plug before the cement injection, pump and scrape to clean the well wall, which is used to separate the lower cement slurry and mud to prevent the cement slurry from being polluted. After the impact, because the lower rubber stopper is hollow, hold the pressure of 2-4 MPa to break the rubber membrane, provide a passage for the cement slurry, and establish a circulation. Then, inject cement, put in the upper rubber plug, pump, bump, and cement the well.

Model

Standard type, anti-transformation

Specifications

20”, 18-5/8”, 13-3/8”, 10-3/4”, 9-5/8”, 8-5/8”, 7-5/8”, 7”, 6- 5/8”, 5-1/2”, 5”, 4-1/2”, 3-1/2”, 2-7/8”

en

en

cn

cn  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  pl

pl  vi

vi  hu

hu

Call us on:

Call us on:  Email Us:

Email Us:  No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China

No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China