| Model | Working Pressure | Features | Recommended service |

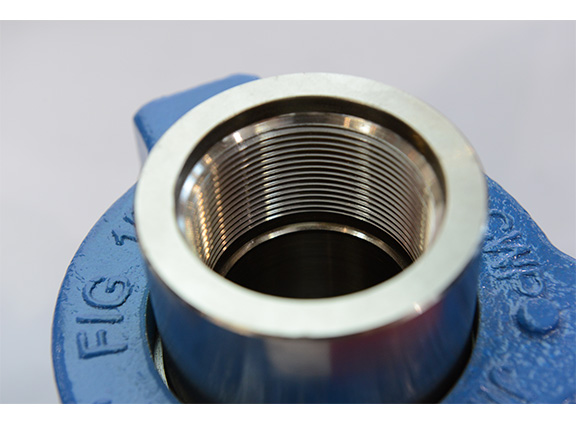

| Fig 100 Hammer Union | 1,000 psi(69 bar) | Pressure-tight make-up with hammer | Manifold and line connections |

| Economical,low-pressure union |

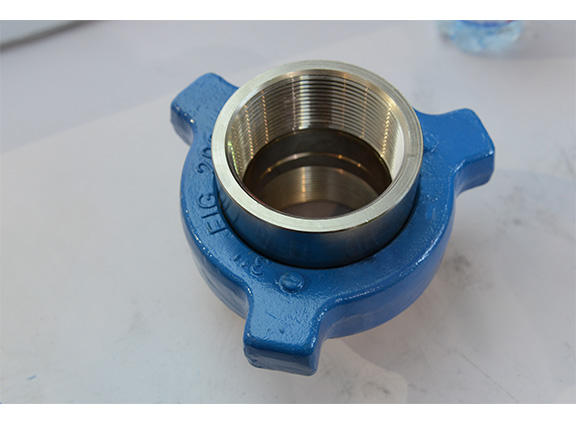

| Fig 200 Hammer Union | 2,000 psi(138 bar) | Economical,general-purpose union | General-service manifolds and lines |

| 1-to 4-inch sizes |

| Butt-weld available |

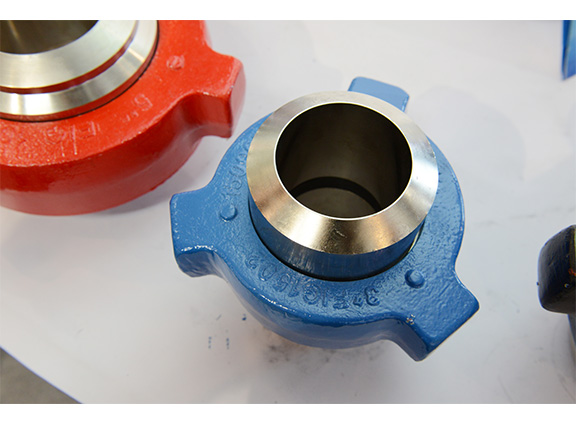

| Fig 206 Hammer Union | 2,000 psi(138 bar) | O-ring in male sub improves sealing and protects metal-to-metal seal against corrosion | Manifold and line connections,suction service,and corrosion service |

| Replaceable O-ring extends union |

| u 1-to 10-inch sizes |

|

| Fig 207 Hammer Union | 2,000 psi(138 bar) | Parts are interchangeable with Figs.200 and 206 | To seal manifold connections and protect union threads |

| O-ring on blanking cap ensures a leak-free seal |

| Raised lugs on cap allow for make-up with a hammer |

| Cap can be tapped for pressure gauge if specified |

| Available in butt-weld |

|

| Fig 211 Hammer Union | 2,000 psi(138 bar) | Laminated insulating rings eliminate all metal-to-metal contact;insulating rings | For production systems with electrolytic corrosion problems |

| Provide 35 million ohms resistance across the union |

| O-ring in male sub provides a positive primary seal |

| Seal ring in female sub provides a positive secondary seal |

| Insulating rings,O-ring,and seal ring can be replaced to extend union life |

|

| Fig 400 Hammer Union | 4,000psi(276 bar)through 4-inch sizes; | 21/2-through 12-inch sizes have O-rings for primary seal | Manifold and line connections,pump suction,and mud service |

| 2,500psi(172 bar)through 5 to 12-inch sizes | Butt-weld available |

| Available for sour gas service:2,500 psi suction,(172 bar)cold working pressure, 5-through 12-inch sizes;4,000psi (276 bar) coldworking pressure, 1-through 4-inch sizes |

|

|

| Fig 600 Hammer Union | 6,000psi(414 bar) | Bronze seat provides primary seal;will not rust in water services | Steam service,boiler connections, manifold,and line connections for production,drilling,and well servicing |

|

| Fig 602 Hammer Union | 6,000psi(414 bar) | Compact | Manifold and line connections and mud service |

| Replaceable,lip-type seal provides primary seal,protects secondary metal-to-metal seal,and minimizes flow turbulence |

| Butt-weld available |

| Available for sour gas service:6,000 psi (414 bar)cold working pressure |

|

| Fig 1002 Hammer Union | 10,000psi(690 bar)through 4-inch sizes; 7,500 psi(517bar),5-and 6-inch sizes | Replaceable,lip-type seal provides primary seal,protects secondary metal-to-metal,and minimizes flow turbulence | Cementing,fracturing,acidizing,testing, and choke-and-kill lines |

| Butt-weld available |

| Available for sour gas service:7,500 psi (517 bar)cold working pressure |

| 5-and 6-inch sizes have O-rings for primary seals |

|

| Fig 1003 Hammer Union | Misaligning union | Ball seat provides positive seal with up to 71/2misalignment;2-inch model up to 4° | For high-pressure connections where lines cannot be aligned |

| 10,000 psi(690 bar)2-and 3-inch sizes; | Replacement O-ring on male sub provides primary seal,and protects metal-to-metal seal against abrasion and corrosion |

| 7,500psi(517 bar),4and5 inch sizes | Hammer union connection:available with threaded or butt-weld ends |

|

|

| Fig 1502 Hammer Union | 15,000 psi(1034 bar) | Replaceable,lip-type seal provides primary seal,protects secondary metal-to-metal seal,and minimizes flow turbulence | Cementing,fracturing,acidizing,testing, and choke-and-kill lines |

| Butt-weld available |

| Available for sour gas service:10,000 psi (690 bar)cold working pressure;butt- weld or non pressure-thread seal configurations only |

|

| Fig 2002 Hammer Union | 20,000 psi(1380 bar) | Replaceable,lip-type seal provides primary seal,protects secondary metal-to-metal seal,and minimizes flow turbulence | Cementing,fracturing,acidizing,testing, and choke-and-kill lines |

| 2 and 3-inch line sizes |

| Butt-weld configurations only |

|

| Fig 2202 Hammer Union | 15,000 psi(1034 bar) | Meets National Association of Corrosion Engineers Standard MR-01-75 and American Petroleum Institute RP-14E | Especially designed for sour gas service |

| Heat-treated components are 100% tested for hardness |

| Fluoroelastomer seal rings |

| Butt-weld only |

| Stamped"sour gas"using low-stress dot stamping and painted with a green zinc-chromate primer to assure quick identification |

|

en

en

cn

cn  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  pl

pl  hu

hu

Call us on:

Call us on:  Email Us:

Email Us:  NO. 1192, Xinhu Street, Dezhou City, Shandong, China

NO. 1192, Xinhu Street, Dezhou City, Shandong, China